Petrochemicals

The chemical sector accounts for as much as 10% of global energy consumption. With energy costs representing a substantial portion of the average petrochemical plant’s operating budget, more efficient use of energy has become critical for maintaining profitability in this competitive industry. And because direct CO2 emissions from primary chemical production amount to 7% of the world’s total CO2 emissions, energy efficiency in petrochemical processing is critical for accelerating global sustainability as well.

Alfa Laval has decades of experience working with petrochemical plants to optimize the efficiency of their processes. We offer a broad portfolio of efficient heat exchangers that make it possible to recover more waste heat, and thereby reduce fuel needs and your carbon footprint, while simultaneously boosting production capacity and minimizing material consumption. With more efficient thermal solutions, you can even save money by, for example, using lower grade steam, or generate additional income by selling off surplus electricity and heat to neighbouring plants.

See the numbers: energy efficiency potential in petrochemical plants

Alfa Laval plate heat exchangers are up to five times more thermally efficient than traditional shell-and-tubes. What difference can that make for your plant? Today, the installed base of our plate heat exchanger technologies in the petrochemical industry saves up to 19 TWh of energy – the same amount that it takes to heat nearly 2 million European homes.

Imagine if every petrochemical plant made the switch to more efficient heat transfer technologies today. We could reduce global CO2 emissions by 28 million tonnes, the equivalent of what’s produced each year by the 3.7 million people living in Qingdao, China.

Want to learn more about how we can help you maximize energy efficiency? Download our infographic to see more numbers.

Customer cases

Reducing energy consumption at India’s largest specialty chemicals plant

Balaji Amines, is the largest producer of methyl amines in India. With a partnership dating back to 2002, they have 86 Alfa Laval heat exchangers installed, and have been continuously impressed with the performance. The improved energy efficiency from just their first eight Alfa Laval Compablocs has resulted in savings of around USD 700,000 per year. More than that, Balaji Amines appreciate the high level of process know-how and professional service their Alfa Laval experts provide.

Cutting emissions and boosting capacity for Dow Wolff Cellulosics in Belgium

When Dow Wolff Cellulosics encountered an urgent issue with a worn-out shell-and-tube reboiler, they turned to Alfa Laval for support. With an eye toward improving energy efficiency, Alfa Laval showed them the potential of replacing two older units with more efficient plate technologies. The result was an annual energy saving of 22,400 GJ with a 1250-tonne reduction in CO2.

Using process energy the smart way at a plant in Asia

A paraxylene plant in Asia is constantly looking for new ways to improve their energy efficiency. With Alfa Laval’s help, their engineers increased heat recovery by more than 23 MW after trading older air-cooled condensers for more efficient plate heat exchanger technologies.

Our solutions

Alfa Laval Compabloc

Alfa Laval Compabloc is the champion of heat exchange: a proven solution for challenging applications. With a counter-current flow that enables crossing temperatures in a single unit, it can offer optimal efficiency for demanding petrochemical duties. The close temperature approach also means cold stream can be heated just a few degrees cooler than incoming hot stream, maximizing heat recovery.

Welded spiral heat exchangers

Alfa Laval spiral heat exchangers are designed to handle the toughest heat transfer challenges. Whether it’s frequent fouling from dirty media, or limitations from pressure drop and floor space, they are the ultimate problem solver for liquid-to-liquid and two-phase duties. With a proven reputation for almost never fouling up, their robust, efficient and compact designs are ideal for challenging petrochemical duties.

Alfa Laval gasketed plate-and-frame heat exchangers

Our wide range of industrial gasketed plate heat exchangers is suitable for a huge scope of petrochemical applications from heating, cooling and heat recovery to condensation and evaporation. Based on our work with customers, we continuously update the industrial line to better meet the demands of your processes. Today’s models set all new standards of efficiency, reliability and serviceability.

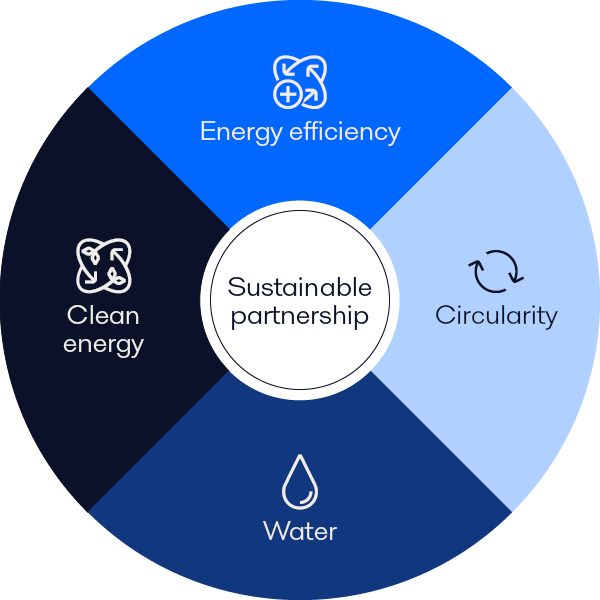

Discover the benefits of partnering with Alfa Laval

Petrochemical producers demand continuous processes and sustainable performance. With a long record of experience partnering with petrochemical plants around the world, Alfa Laval has the knowhow to support the challenging process demands on which your business relies. Count on us for highly efficient solutions that do the toughest jobs with consistency, quality and reliability.

Our petrochemical experts can partner with you from start to finish. We closely work with you to design the most efficient and profitable system for your processes. And thanks to our comprehensive service network, we have service engineers – and genuine Alfa Laval spare parts – on hand around the clock, anywhere in the world.