Circular economy

Today we live in a linear, take-make-waste economy. Products are used and thrown away, denying us access to still valuable and often scarce natural resources, and further contributing to pollution. In a circular economy, however, the entire product lifecycle is designed to eliminate waste and pollution. When one product is no longer viable, its materials and components are put back into use in other ways. Everything is recirculated, leading to the regeneration seen in natural systems.

Thanks to our unique understanding of separation and thermal technologies, Alfa Laval has led the way in the development of new solutions to advance the circular economy. Today we can help you improve resource efficiency and the reduction, reuse, and recycling of waste to optimize your production processes for more reliable and sustainable performance. Together, we can accelerate the transition to a circular economy for bio-based chemicals, bioplastics, biofuels, municipal solid waste (MSW), zero liquid discharge (ZLD), recycling of plastics, textiles and more.

Defining the circular economy

The circular economy, as defined by the Ellen MacArthur foundation, is based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.

In other words, nothing go to waste and all our natural resources are used in the most efficient way, again and again. Products are produced using renewable energy. Within production processes, water, chemicals and materials are reused, reduced and recycled. By-products are extracted to enter other circular systems. The product is then used for as long as possible. If broken, a product is repaired instead of thrown away. At the end of a product’s lifecycle, its constituent components are recycled, to be put back in to production again, completing the circle. Biological material that is not recycled instead degrades, renewed with sunlight, CO2 and nutrients to enable the growth of new natural resources.

This will, of course, be a huge change for industry, but a necessary one. Is your operation ready to transition to a circular business model? If so, contact us today to learn about the many ways our solutions can help you achieve your goals.

Mapping the green transition

Learn how to maximize your sustainability goals and practices. Download the eBook on Benchmarking Progress in Canada’s Manufacturing and Industrial Sectors today and work towards a greener tomorrow.

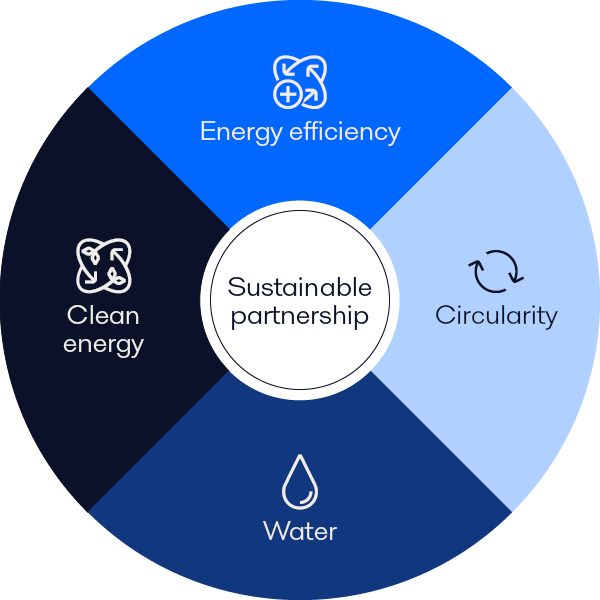

A pioneering partnership from two sustainability leaders

Alfa Laval and Stena Recycling have teamed up create a smart, sustainable and easy-to-use solution for improving circularity in our industry. Called Re-Made to matter, this new exchange programme will make it possible to recover as much as 100% of the valuable metals found in old heat exchangers. By replacing them with more modern designs, we can also enable efficiency improvements for energy savings as well as a reduced carbon footprint.

Circular solutions to turn waste into value

Alfa Laval has brought its expertise in mechanical and thermal separation to a partnership with EasyMining. Part of the Swedish Ragn-Sells Group, EasyMining is an innovation company dedicated to enabling new circular solutions. With Alfa Laval’s support, they are making it possible to extract phosphorus from incinerated waste sludge and other resources from waste streams – creating new value chains for waste materials.

“With these processes it will be possible to transform waste into valuable products again, which is a key step in building a more sustainable society,” says Susanne Pahlén Åklundh, President of Alfa Laval’s Energy Division.

“With Alfa Laval, we see the possibility of speeding up the development and commercialization of our processes, which is important for innovation companies,” says Jan Svärd, CEO of EasyMining.

Resource efficiency

What does it really mean to use resources more efficiently? Ultimately, it’s about increasing yield by, of course, getting the most out of every raw material, but also ensuring that absolutely nothing goes to waste.

When done right, resource efficiency not only improves the sustainability of your operation. It can also be a smart way to cut costs and boost profitability. From green and bio-based chemicals to natural refrigerants, Alfa Laval has the diversity of solutions and expertise to help you improve the circularity of your resource consumption. Learn how we can support your industry today.

Reuse, reduce & recycle

Most industrial processes today consume a great deal of natural resources and produce significant amounts of waste as a result. With the right technology, however, it has become increasingly possible to minimize waste output and thereby shrink both your environmental footprint and operational costs.

Alfa Laval has extensive experience supporting customers with on-site treatment and recovery solutions that enable improved management of your waste and water streams. Our highly efficient separation and water management solutions can help you reduce, reuse and recycle waste in all new ways.

Product lifetime

Ensuring sustainability in the circular economy also means optimizing and maximizing the lifetime performance of each product.

At Alfa Laval, this is a major part of how we consider the designs of our equipment and the materials we use. We work with customers to ensure our products are operated in the optimal way to ensure long-lasting, efficient performance. Our comprehensive service portfolio ensures every Alfa Laval customer has the right support to get the best lifetime operation from their equipment. In some cases, we can even advise on how the product can be reused and recycled at the end of its life.

Accelerating circularity for Outokumpu

Outokumpu, the global leader in stainless steel, reduced its carbon footprint by improving the circularity of liquid resource consumption in their degreasing process. Being able to reuse more of the liquid for longer, helped them improve production efficiency, and also resulted in less scrap and better quality in the final products. Watch this video to learn more.

Presence across all sectors

Thanks to leading separation and heat transfer innovations, Alfa Laval has a broad presence across a wide range of industrial applications. Want to learn how we can help you improve the circularity of your operations? Select your field from the list below.

Zero Liquid Discharge (ZLD)

Alfa Laval ZLD systems are robust, compact solutions designed for the absolute minimization of liquid discharge in a wide range of industrial waste applications. ZLD systems optimize the efficiency of your water consumption via a combination of thermal solutions and separation technology, with the AlfaFlash evaporator at the core of the set up.

Bio-based chemicals

Chemicals and materials from various biomass sources play an important role when it comes to reducing our dependence on non-renewable resources. Trees, plants, crops, algae, bacteria and biological waste can be used in their different shapes and forms to produce a wide range of bio-based chemicals, fuels, products and intermediates. Alfa Laval can help you improve efficiency and sustainability in a wide range of bio-based chemical applications.

Recycling

In the circular economy, the last product lifecycle phase is recycling. This enables us to take advantage of the components and natural resources within the product, returning them to production. Today, emerging processes are creating new possibilities for the commercialization of recycling processes for plastics, textiles, batteries, municipal solid waste (MSW) and more.

Sustainability and your plant: Energy efficiency

Are you under pressure to contribute to the overall sustainability goals of your plant? Navigating energy efficiency at your facility can often feel like an overwhelming challenge. Our free guide can help you get started.