2022-10-04 Product news

$175 Million District Energy Investment in Richmond, B.C.

The financing will allow for more than 170 new residential and mixed-use commercial development sites in the Richmond, B.C. area by 2050.

This article is related to Canada’s commercial HVAC industry. Alfa Laval provides energy-saving compact plate heat exchangers to many commercial premises, industrial facilities and public buildings in Canada.

View the full article on foodincanada.com

“…The Canada Infrastructure Bank (CIB), Lulu Island Energy Company (LIEC) and Corix Infrastructure Inc. (Corix) have closed on a district energy expansion project in Richmond, British Columbia.

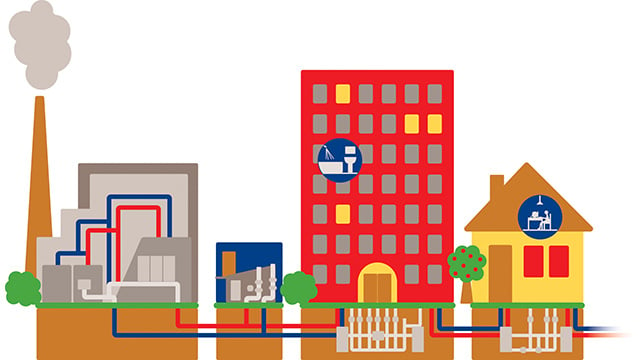

Under the agreement, the CIB will provide $175 million in financing for the LIEC City Centre District Energy Utility project. It will enable expansion to more than 170 new residential and mixed-use commercial development sites in the area by 2050, using low-carbon heat recovered from the Gilbert Road regional sewer system.

When complete, the project is expected to reduce greenhouse gas emissions by one million tonnes by 2050, with the amount of connected space to the district energy system increasing 10–fold to 50 million square feet...”

Click here to learn more about Alfa Laval’s heat exchangers for the cooling and heating of air and water in buildings.

Tags

All

District heating renovation, Odessa

The makeover included new boilers, pipes, heat exchangers and substations. The result: total energy savings of up to 50%.

A modern district heating network

The new system replaced a traditional, dual-circuit network design characterized by high water flows, inflexible heat supply and excessive hot water tapping. Instead, a modern 3-circuit solution was introduced, with circuits for production, distribution and household consumption. The circuits are separated by plate heat exchangers and substations from Alfa Laval. Previously, consumption was controlled by only three large substations. These were now replaced by 40 small and efficient substations from Alfa Laval – one per building served.

Plate heat exchangers

Several large Alfa Laval plate heat exchangers separate the production and distribution loops of the network, while transferring the heat. Thanks to the high thermal efficiency of these heat exchangers, temperature and pressure levels, as well as the water flows, can be kept relatively low. This means less water needs to be produced by the boilers. It also allows for smaller piping dimensions and pumps throughout the system. The individual substation in each building captures exactly the heat needed for space heating and produces the hot tap water locally.

Massive energy savings

The district heating renovation project in Odessa has become a model for other Ukrainian cities. And the results are impressive: total energy consumption has dropped by 50% (enough to heat 800 single homes in Sweden), direct system costs are down by 30%, electricity costs by 40% and water consumption by a stunning 95%. In addition, CO2 emissions are reduced by 3,800 tonnes per year.