Olive Oil Booster

The Olive Oil Booster system, when integrated into an olive mill, enhances decanter performance. When combined with the olive crusher and vertical centrifuge, it results in significantly higher olive oil extraction quantities and increased antioxidant components compared to conventional olive oil equipment. This innovative solution not only boosts yield but also improves sustainability by reducing water consumption and operational costs.

Experience the benefits of the Booster throughout the entire harvest season

- Achieve optimal olive oil yield thanks to innovative technology combined with efficient processes

- Enhance olive oil quality by increasing phenol extraction. This means healthier, longer-lasting oil with a higher retail value

- Low water consumption together with a higher process capacity

- Maximum free oil release boosts paste preparation and olive oil decanter performance

Profitability boost through improved yields, oil quality and cost efficiency

The Olive Oil Booster improves oil mill profit margins by increasing yields of better-quality oil and cutting operational costs. It helps reduce process water consumption and by consequence the water disposal, lowering both costs and environmental risks. With higher extraction rates per Kg of olives, Alfa Laval olive oil system is efficient also from energy consumption point of view.

The features that make the difference

Everything you need to meet your challenges today – and tomorrow

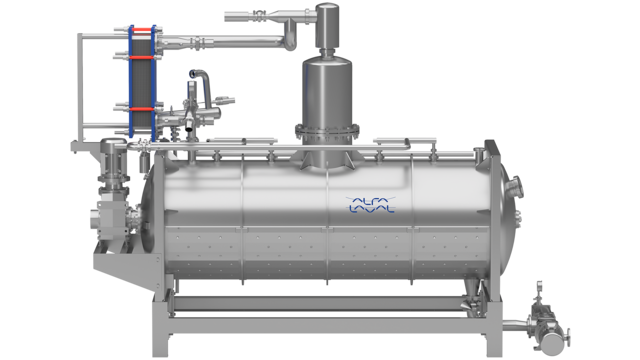

The Olive Oil Booster system is a combination of different technologies working together to maximize oil yield and quality in oily fruit processing. The equipment uses a “low” vacuum, enabling processes that are not feasible under atmospheric pressure. This provides significant benefits when processing materials sensitive to heat and oxygen.

Low Vacuum Technology

Vacuum conditions provide enormous advantages in pre-treatment processes for food products sensitive to temperature and oxygen, which would not be obtainable at atmospheric pressure.

Improved Oil Extraction

Preparing oily fruit pulp under low-vacuum conditions helps the oil droplets come together, reduces emulsions and interactions with microgels and improves the performance of the decanter. This leads to better extraction and higher oil yield compared to conventional malaxing technology at atmospheric pressure.

Improved Oil Quality

Vacuum conditions increase liquid flow into solids, enhancing phenol migration to oil and preserving aromatic compounds by removing air and preventing aroma loss.

Energy savings

Improved extractability and decanter efficiency reduce energy consumption per kilogram of oil extracted. Vacuum conditions improve performance at low temperatures, saving heating energy.

In addition, vacuum preparation of the fruit's oily pulp improves extraction by centrifugation, significantly reducing water dilution in three-phase decanter extracti

How does the Olive oil Booster help maximize olive oil yield while improving olive oil production?

The Alfa Laval Booster system is designed to replace the conventional malaxer step for paste preparation in oil mills. This mechanical method is capable of de-aerating the olive paste while controlling the temperature, resulting in key process and performance benefits. The innovative system works with a combination of thermal and separation solutions, with Plate Heat Exchanger (PHE) and olive oil decanter centrifuge as core technologies. This is what makes Alfa Laval Olive Oil system a class-leading technology, while maintaining the traditional process flow, as can be seen following it step by step:

Step 1. Crushed olives are transferred into the booster

As seen in traditional oil mills, olives are crushed, and the resulting olive paste is promptly transferred into the Booster under a specified vacuum pressure. The vacuum pressure facilitates rapid cooling and the removal of oxygen, as the temperature of the olive paste after crushing exceeds the boiling point of water.

Step 2. Booster release of “oil free” from the olive paste

Olive paste is agitated by the horizontal shaft with blades for a certain time at a settled pressure (deep vacuum) and temperature. Keeping the vacuum pressure below the boiling pressure at a settled temperature (i.e. 18°), olive paste is kept under boiling condition where a certain amount of water change physical phase from liquid to vapor.

The boiling at cold condition of olive paste is capable to produce bigger oil drop and higher amount of “free oil” rich in phenols compared to the traditional malaxing, with a consequent significative increase of oil yield of higher quality. The energy necessary for this physical phase change is given by hot water circulating into the jacket of vacuum tank heating the olive paste.

The little quantity of vapor produced during exposition of olive paste to the vacuum is condensed by a plate heat exchanger with cold water produced by a chiller and the little quantity of condensate vapor is returned to the olive oil extraction process. Because the paste is boiling at low temperature, there is not negative effect on the amount of positive aroma compounds of olive oil. On the contrary, some negative aroma compounds with light molecular weight such as ethanol, acetic acid and ethyl acetate can be removed from the oil by the Olive Oil Booster technology.

This step of “free oil” release could be obtained entirely by the Olive Oil Booster, or by using it in combination with traditional malaxing.

Step 3. Separate the oil with a decanter centrifuge

The Olive paste prepared by the olive oil equipment is fed into the decanter centrifuge where the oil is separated from water and solids, working in two or three phases. Performance of the olive oil decanter in terms of capacity, oil clarity, residual oil in the husk and quantity of dilution water (in case of three phases), is strictly depending on the characteristics of the olive paste prepared during the previous operation.

Step 4. Improved oil clarification

Oil from the decanter – featuring fewer impurities – improves the capacity of the high speed separator to purify the final product and reduces any downtime needed for cleaning.

With traditional malaxation system, the results on free olive oil production and oil drop dimension are strictly depending on many variables such as fruit ripeness, fruit moisture, fruit variety, crushing technology, etc. The paste preparation made by the Olive Oil Booster is globally improved in terms of oil drop dimensions and production of “free oil” with respect to traditional method. This improvement is obtained independently from fruit characteristics when compared with traditional method.

All this is traduced in a significant improvement of performance of the separation in the olive oil decanter with clear advantages in the reduction of the residual oil in the husk, increase of throughput capacity, improve of oil clarity and reduction of dilution water quantity when used. Improved oil clarity obtained by the decanter after the Alfa Laval Olive Oil system is also an advantage for the improved performance of vertical centrifuge for oil purification. An oil with fewer impurities from the olive oil decanter improves the efficiency of the vertical centrifuge and decreases the frequency of cleaning interruptions

Suitable to avocado oil processing

A line installation featuring combinations of an Alfa Laval decanter centrifuge and a Booster extraction unit is ideal for production of olive as well as avocado oil. It can also be used for other processing setups with origins in oily fruit. The equipment uses a “low” vacuum, enabling processes that are not feasible under atmospheric pressure. This provides significant benefits when processing materials sensitive to heat and oxygen.

Enjoy the benefits of the olive oil booster

Producing high-quality olive oil in the most cost-effective way possible is a priority for many olive oil mills, while also highlighting the quality of their products. Alfa Laval booster models can be configured in series of several units to suit the size/capacity of decanter centrifuges.

Watch this video and discover this cutting-edge solution that delivers significantly more “free oil” and a significantly higher phenol content in the extracted olive oil.

Olive oil extraction success stories

Alfa Laval olive oil technology allows to increase income results without increasing the operating cost. Making easier the oil extraction from fruit pulp, Olive Oil Booster is capable to reduce the consumption of the process water and by consequence the water disposal, with reduction of cost and environmental risk.

Watch the case story video now

Documents

Download the white paper to find out how to maximize oil yield and quality

Service

Extending the performance of your equipment

For the market’s widest portfolio of heat transfer, separation and fluid handling equipment, Alfa Laval offers an unmatched range of services and support. From assistance during installation and commissioning to routine maintenance options and expertise to solve tough challenges, we are here to make sure your equipment delivers the performance you expect for a long time to come.

Our global network of service centers is staffed by maintenance technicians with extensive process and product knowledge. No matter where you are, we make sure you have a local contact who can be onsite with the experience to meet your needs.

Contact us to learn more.

Contact us

Let us help you

The latest olive oil production systems can be retrofitted to an existing processing line or delivered as part of a new oil plant. Boosters are normally used in combination with several other technologies to increase the yield of high-quality oils, thereby improving the olive mill's profitability. In synergy with an olive crusher, decanter centrifuge and vertical centrifuge, they allow for the extraction of significantly higher quantities of olive oil along with a higher quantity of antioxidant components. Would you like to know more? Let us help you.